Telling you to loctite the two bolts in place basically..

cover the water pump gasket with grease , fit water pump and put the bolts in.. all bolts until you feel the bolts pinch slightly

Take 1 and 5 back out, degrease them, and the holes ( brake and clutch cleaner in a spraycan for this) dab of loctite on each put them in and tighten all bots up..

Fill reservoir so it just covers the base of the bottle..

Now carry on putting cambelt on, this will give time for the coolant to fill the block up.

As you will be turning the water pump pulley..

Make sure the water pump pulley is degreased after using the grease for the gasket..

ANY HIGH MELTING POINT GREASE WILL DO

The only grease products I have are these:

Confused by all the greases out there? Come and meet the ProSlip Angels who will sort out your lubrication problems! We're talking brake grease here boys.

proslip.com

The clip and pad grease are more of a dry lubricant. Pin grease should be OK. Feels like how a grease should if you get what I mean and can withstand 200c.

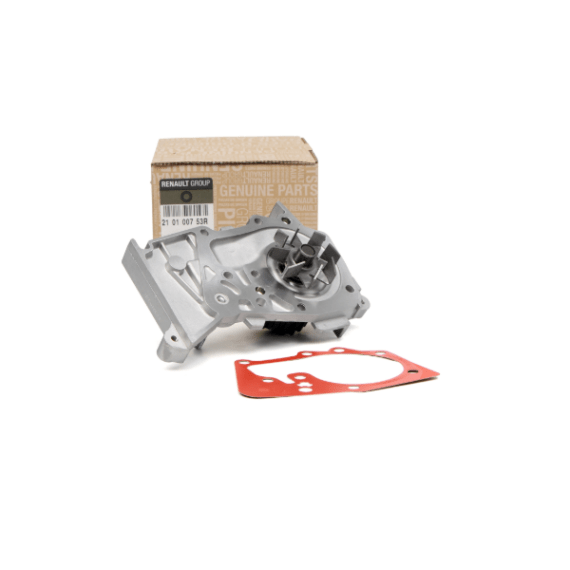

Here's the type of gasket my pump uses anyway. I think it is called a paper style gasket:

Renault Twingo 133 Water Pump - Renault Parts Direct - Renault Parts Direct is a web based service from our authorised Renault dealer.

www.renaultpartsdirect.co.uk

Also have copper grease, but probably not suitable for aluminium (mixed metal contact corrosion/galvanisation).

Last but not least I have this too. Would this be better? A smear on both sides of the gasket?

Repair exhausts and head gaskets quickly and easily with the Halfords range of gasket sealers and exhaust repair supplies. Same day click & collect available

www.halfords.com

Edit: Just been reading on that, and people suggest it is not good to use sealant and paper gasket together. So hopefully you approve of that pin grease

@ours2012 because it is all I've got.

I can't go out and buy a tub of grease and can't wait for delivery either. Flooding is extremely bad in my area.

i did the same job on my cabriolet, in the street, jan,sevral years ago, if i remember. brass monkeys etc. i got a checklist on this forum and followed it for setting up the timing. started first turn. i had to do the head, two valves, cam seals, waterpump etc. the waterpump kit came with tensioner installation advice. still driving and idles like a sewing machine. getting sensible, practical advice here helped hugely.

Glad it is all running good.